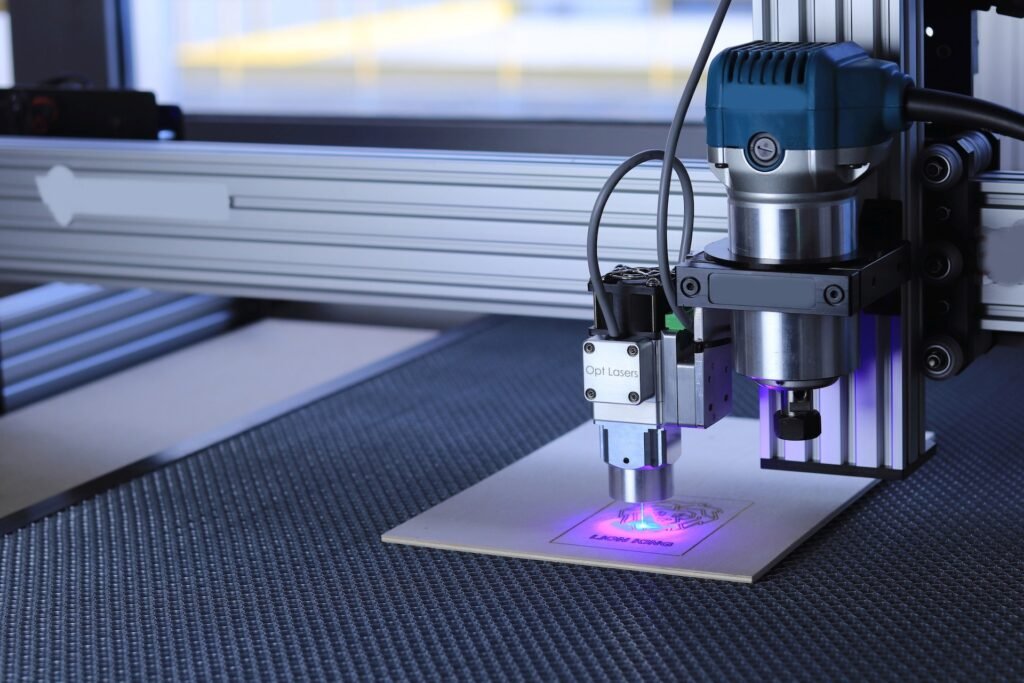

In the realm of modern manufacturing and product identification, Fiber Laser Marking Machines have gained significant prominence. These advanced tools utilize the power of fiber lasers to create precise and durable markings on various materials. Let’s delve into the world of Fiber Laser Marking Machines, exploring their capabilities and diverse applications.

Speed and Precision:

Fiber Laser Marking Machines are known for their remarkable speed and precision. They can etch or mark intricate designs, barcodes, serial numbers, and logos on materials like metals, plastics, ceramics, and more. This precision ensures that the markings remain clear and legible, even in demanding industrial environments.

Diverse Material Compatibility:

One of the standout features of Fiber Laser Marking Machines is their ability to work with a wide range of materials. From stainless steel and aluminum to delicate plastics and ceramics, these machines offer unmatched versatility. This capability makes them a go-to choice for industries ranging from aerospace and automotive to medical and electronics.

Non-Contact Process:

Fiber laser marking is a non-contact process, which means that it does not require physical contact with the material. This not only prevents damage to the surface but also allows for the marking of fragile or heat-sensitive materials, ensuring product integrity.

Permanent and Durable Markings:

The markings created by Fiber Laser Marking Machines are permanent and highly durable. They are resistant to wear, corrosion, and fading, making them ideal for applications where longevity is crucial. This durability is particularly valuable in industries like jewelry making, where product quality is paramount.

Versatile Applications:

Fiber Laser Marking Machines find applications in a wide array of industries. In the medical field, they are used to mark surgical instruments for traceability and quality control. In the automotive sector, they mark critical components with part numbers and serials for identification and tracking. Additionally, these machines are indispensable in the production of consumer electronics, where precise labeling and branding are essential.

Cost-Effective and Eco-Friendly:

Fiber Laser Marking Machines are cost-effective in the long run. They have low maintenance requirements and consume less power compared to other marking technologies. Their eco-friendliness extends to the minimal waste produced during the marking process, aligning with sustainable manufacturing practices.

In conclusion, Fiber Laser Marking Machines have revolutionized the way products are identified and labeled across various industries. Their speed, precision, versatility, and durability make them a preferred choice for manufacturers looking to enhance product traceability and branding. As technology continues to advance, Fiber Laser Marking Machines are poised to play an even more significant role in ensuring product quality and compliance while reducing the environmental footprint of manufacturing processes. Whether you are in aerospace, healthcare, or consumer electronics, the power of Fiber Laser Marking Machines is an invaluable asset for your business.