CNC Router Machines: Shaping the Future of Precision Manufacturing

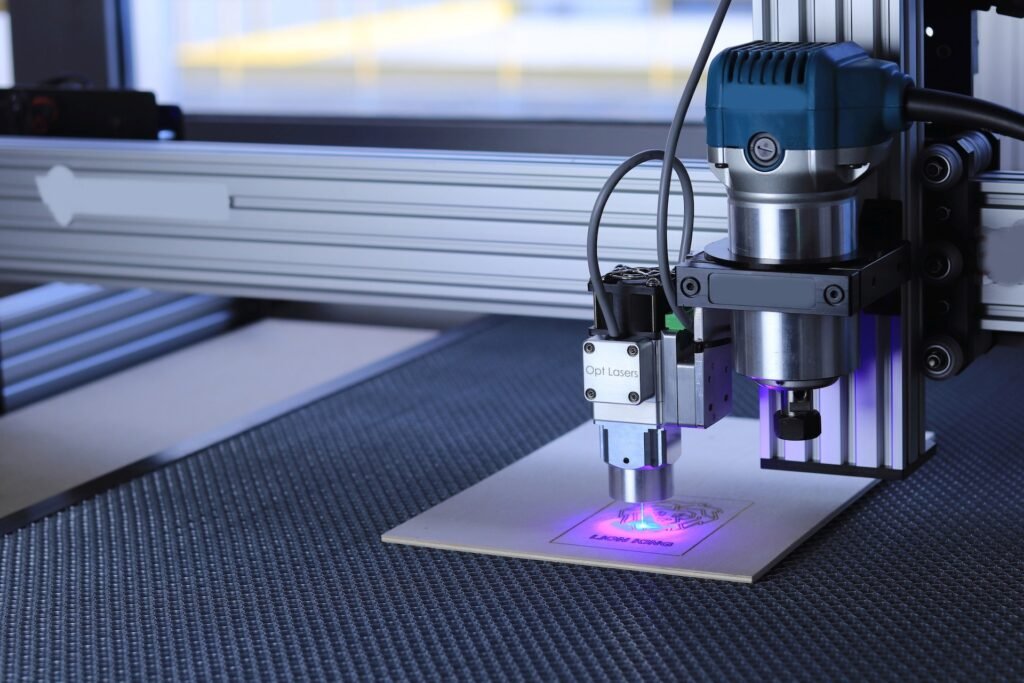

In the world of precision manufacturing, CNC (Computer Numerical Control) Router Machines have emerged as versatile workhorses that empower businesses to craft intricate designs and shapes with unparalleled accuracy and efficiency. Let’s explore the fascinating world of CNC Router Machines and how they are shaping the future of manufacturing. Precision and Accuracy: CNC Router Machines are renowned for their precision and accuracy. They operate with mathematical precision, ensuring that every cut, carve, or engraving is executed with consistency and repeatability. This precision is essential in industries such as woodworking, sign-making, and aerospace, where intricate designs and exact measurements are non-negotiable. Versatility in Material Compatibility: One of the key strengths of CNC Router Machines is their ability to work with a wide variety of materials. Whether it’s wood, plastics, metals, foam, or composites, these machines can adapt to the task at hand. This versatility allows businesses to explore new product ideas and expand their offerings. Customization and Personalization: In the age of customization, CNC Router Machines provide manufacturers with the ability to create bespoke products. From personalized wooden gifts to intricately carved architectural elements, the CNC router’s flexibility empowers businesses to cater to individual preferences and unique customer demands. Time and Labor Savings: CNC Router Machines significantly reduce the need for manual labor and minimize production time. They can operate around the clock with minimal supervision, increasing productivity and efficiency in manufacturing operations. This not only saves time but also reduces labor costs. Complex Geometric Shapes: Creating complex geometric shapes and designs can be a challenging task without CNC technology. These machines excel in sculpting 3D shapes, intricate patterns, and complex contours that would be nearly impossible to achieve with traditional tools. In conclusion, CNC Router Machines have revolutionized precision manufacturing by offering unparalleled accuracy, versatility, and customization options. These machines are not just tools; they are enablers of innovation and efficiency, driving businesses across various sectors to new heights of productivity and creativity. As technology continues to advance, CNC Router Machines are set to play an even more significant role in manufacturing, enabling businesses to meet the growing demand for precision and customization in a sustainable and cost-effective manner. Whether you are in woodworking, aerospace, or the arts, CNC Router Machines are a valuable asset that paves the way for endless possibilities.

CNC Router Machines: Shaping the Future of Precision Manufacturing Read More »